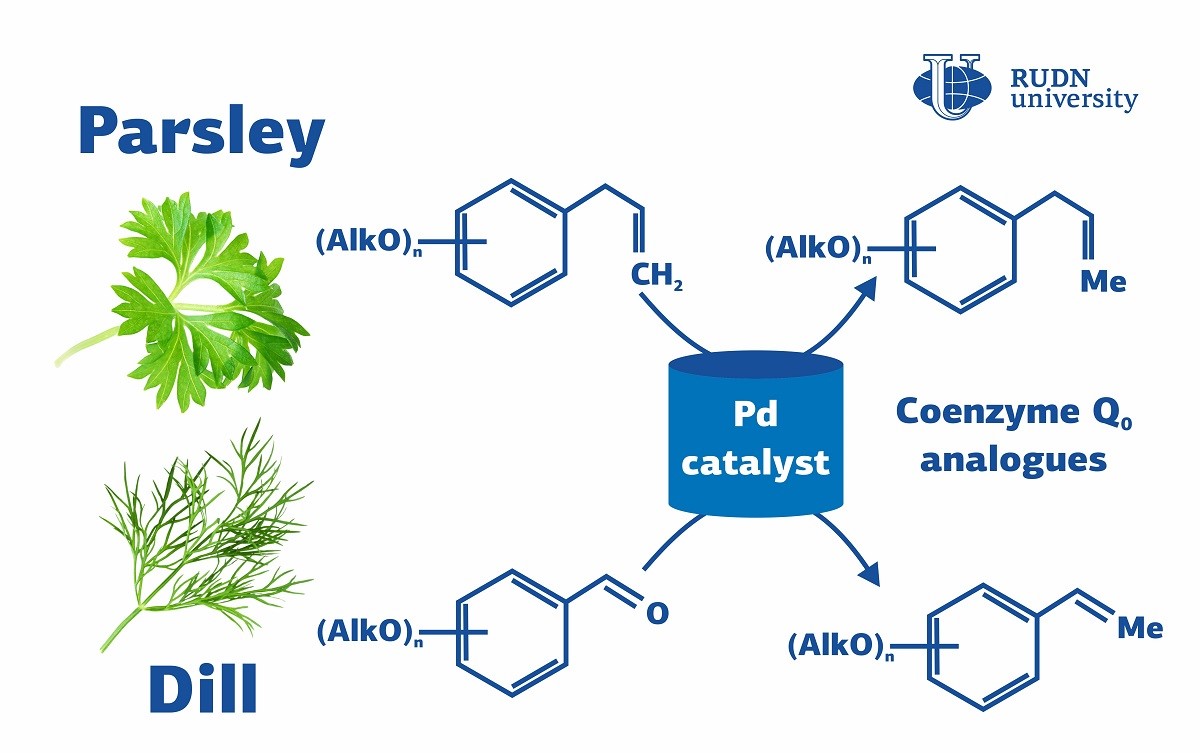

RUDN University Chemists obtained coenzyme from Parsley and Dill seeds

Coenzymes of the Q group in mammals and plants are responsible for maintaining the energy metabolism of cells. They are powerful antioxidants and regulate the permeability ofmitochondrial membranes. Coenzyme Q0 is known to reduce and even suppress metastasis in breast, skin and ovarian cancers.

“We proposed a simple way to obtain the necessary element for the synthesis of Q0 precursors based on allylpolymethoxybenzenes. It is easy to isolate them in large quantities from parsley and dill extract,” says RUDN scientist Viktor Khrustalev.

The main stage on the way of obtaining a coenzyme is hydrogenation to allylpolymethoxybenzenes fragments. This process takes place in a special apparatus with a fluoroplastic insert using aporous palladium catalyst. After use, the reaction mixture is separated from the catalyst without additional filters.

The minimum reaction time is 4 to 8 hours. However, with an increased hydrogen pressure,the reaction takes 2-4 hours. Even with accelerated production, no methylbenzene by-products remain after hydrogenation, which simplifies further purification. The catalyst canthen be used up to 40 times.

"With the help of X-ray diffraction analysis, we have confirmed the spatial structure of there sulting compound. This allows further study of its antitumor and antioxidant properties,"explained Viktor Khrustalev, Doctor of Chemistry, Head of the Department of Inorganic Chemistry of the Peoples’ Friendship University of Russia.

Matilda Pavlovna Mityaeva was born in 1925. In November 1942, she volunteered for frontline duty. She participated in the Great Patriotic War from November 1942 to June 1945 as part of the 53rd Infantry Division of the 475th Infantry Regiment. She was wounded twice.

The team led by Sergey Zyryanov, Head of the Department of General and Clinical Pharmacology, became the winner of the All-Russian competition of scientific projects "Technologies for Human Health".

RUDN University constantly adapts to the changes of the modern world and responds to challenges flexibly. This allows us to keep the standard of a world-class research university. The sphere of science is no exception. Peter Dokukin, Head of the Research Division, presented the updated R&D Programme at the meeting of the RUDN University Academic Council.

Matilda Pavlovna Mityaeva was born in 1925. In November 1942, she volunteered for frontline duty. She participated in the Great Patriotic War from November 1942 to June 1945 as part of the 53rd Infantry Division of the 475th Infantry Regiment. She was wounded twice.

The team led by Sergey Zyryanov, Head of the Department of General and Clinical Pharmacology, became the winner of the All-Russian competition of scientific projects "Technologies for Human Health".

RUDN University constantly adapts to the changes of the modern world and responds to challenges flexibly. This allows us to keep the standard of a world-class research university. The sphere of science is no exception. Peter Dokukin, Head of the Research Division, presented the updated R&D Programme at the meeting of the RUDN University Academic Council.