The story of how it took one 23-year-old engineer a day to remake swimming masks into medical

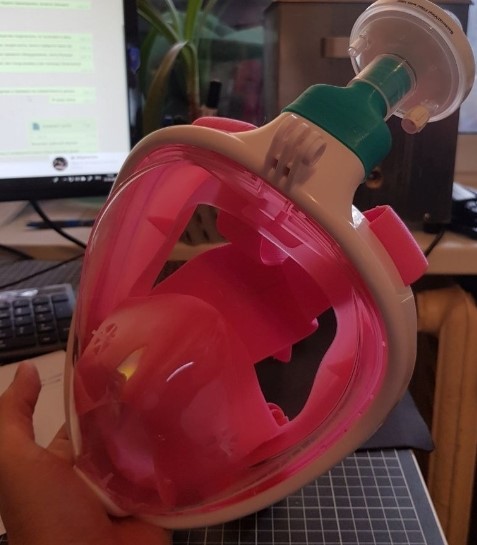

At the beginning of the epidemic, when medical institutions faced a shortage of personal protective equipment in the “red zone”, in Italy they came up with a technology how to make a medical mask for doctors from a swimming mask. Decathlon company was ready to give diving masks to hospitals. However, to use these masks, it was necessary to attach a special filter requiring an adapter. At the same time, the masks were of different models each needing specially designed additional parts.

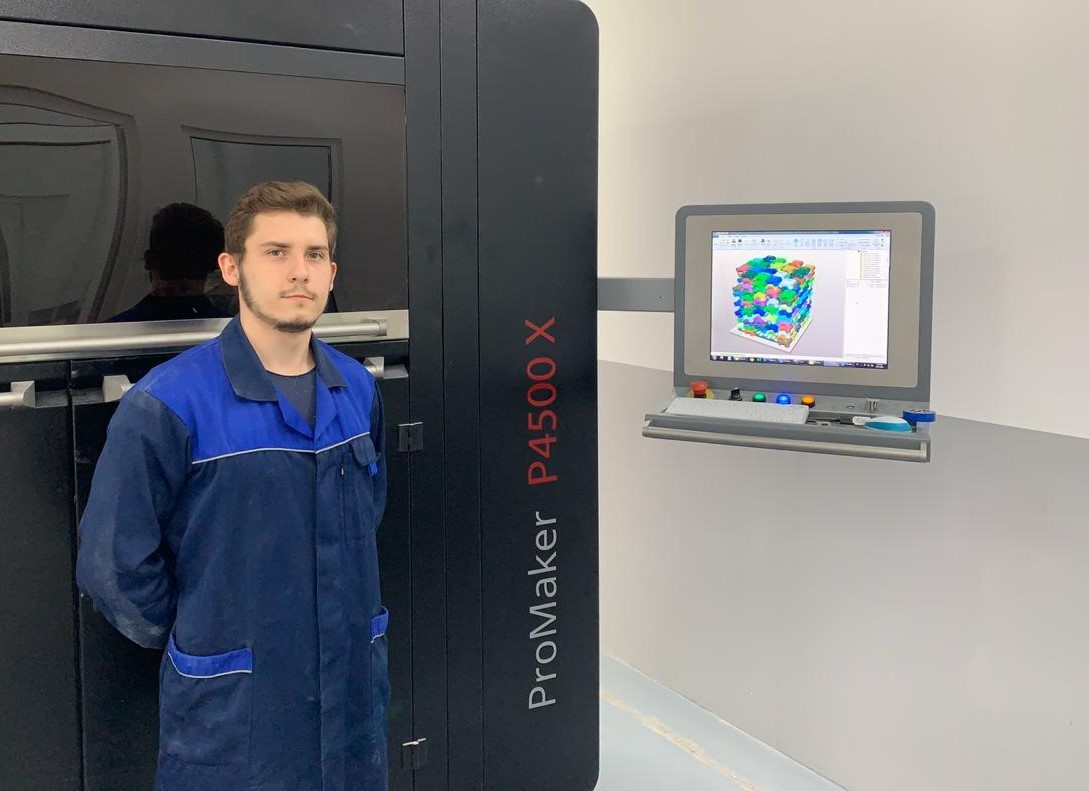

Regular manufacturing would have been long and expensive, because first it would have taken producing molds for thermoplastic machines for each part and each machine separately. RUDN University Institute of Innovative Engineering Technologies (IIIT) proposed using additive, SLS (selective laser sintering) technologies and printing parts on Farsoon SS403P industrial 3D printers (Prodways x 4500).

It took RUDN Additive and Edge Technologies Center just one day to launch the production of adapters of the required parameters from certified medical plastic. Work included setting the task for the 3D printer, printing and cooling of the parts themselves, extracting and cleaning. In a day, 400 adapters of the required parameters were printed, and after two days, the Blokhin Cancer Center and the Mukhin City Clinical Hospital received the first batches of adapters and got effective and comfortable masks. Since most employees are in lockdown, part of the industrial design and logistics work was done remotely. The entire production was performed by only one engineer-technologist of the Center —a 23-year-old Mark Dyachenko!

"We began to print adapters for diving masks when it became clear that doctors lacked personal respiratory tract protective equipment. The adapter is installed on the top of the mask, to which 1 or 2 filters are attached. Each printing round makes 400 adapters, as soon as I took out the printed parts, I immediately prepared and started a new print. While the machine was printing parts, I cleaned the finished product. To print adapters, we used special medical plastic, absolutely harmless to the human body. Due to lockdown the work became more complicated, but we were always in touch with colleagues using messengers. I know that the doctors were grateful to us, and the page of one of the charitable organizations had a post with photos of our adapters and a mention of my name" - Mark Dyachenko, engineer-technologist at RUDN Additive and Edge Technologies Center.

Now RUDN has already manufactured 1,149 filter adapters for 3 mask models. Every seventh swimming mask in Russia, has become a mask for the doctors’ protection thanks to the 3D production of the Peoples’ Friendship University of Russia. They are used in 15 medical institutions in Moscow and the Moscow region.

Engineers at the Institute of Innovative Engineering Technologies at RUDN University have begun manufacturing face shields fasteners and hose holders for lung ventilators — 290 holders are already made. University experts continue experiments to improve enhanced protection medical masks.

Reference:

During one month more than 15 medical institutions in Moscow and the Moscow Region received masks with filters adapters manufactured by RUDN University:

- A. Vishnevsky hospital

- Meditsina JSC (Academician Roytberg’s Clinic)

- O.Mukhin Clinical Hospital

- M.Vladimirsky hospital

- I.Davydovsky State Clinical Hospital No. 23

- State Clinical Hospital No. 52

- N.Bauman State Clinical Hospital № 29

- V.Veresaev State Clinical Hospital No. 81

- Hospital for War Veterans No. 2

- Hospital for War Veterans No. 3

- Mozhaisk Central District Hospital

- N. Blokhin Cancer Center

- A.Vishnevsky Surgery Hospital

- Center for Family Planning and Reproduction

- Russian Railways Central Clinical Hospital

The project to develop a cellular model of the placenta became the winner in the Scientific Materials category of the Young Scientists 3.0 competition, organized with the support of the Presidential Grants Foundation and T-Bank.

Ten scientific journals published by RUDN University have been included in the highest level of the state list of scientific publications, the White List.

Forests are not only the lungs of the planet, but also home to millions of species. However, it has remained unclear how underground interactions between trees and fungi affect forest species richness in different climatic conditions. Previous studies have yielded conflicting results: in some regions, the dominance of certain fungi reduced tree diversity, while in others it increased it.

The project to develop a cellular model of the placenta became the winner in the Scientific Materials category of the Young Scientists 3.0 competition, organized with the support of the Presidential Grants Foundation and T-Bank.

Ten scientific journals published by RUDN University have been included in the highest level of the state list of scientific publications, the White List.

Forests are not only the lungs of the planet, but also home to millions of species. However, it has remained unclear how underground interactions between trees and fungi affect forest species richness in different climatic conditions. Previous studies have yielded conflicting results: in some regions, the dominance of certain fungi reduced tree diversity, while in others it increased it.