RUDN chemists improved the method of extracting natural antioxidants from bay leaves

Isolation of the desired compounds from plant materials by traditional methods takes a lot of time and a large amount of solvent. One of the promising technologies is mechanochemical processing, in which raw materials are processed mechanically to destroy cell walls before extraction. This treatment does not require solvents and reduces production costs. However, there are still very few studies on the use of mechanochemistry for the extraction of natural compounds.

Rafael Luque, Director of the scientific center “Molecular Design and Synthesis of Innovative Compounds for Medicine”, RUDN University, and his colleagues from the University of Cordoba have developed a mechanochemical method that allows obtaining the right compounds from bay leaves processing waste.

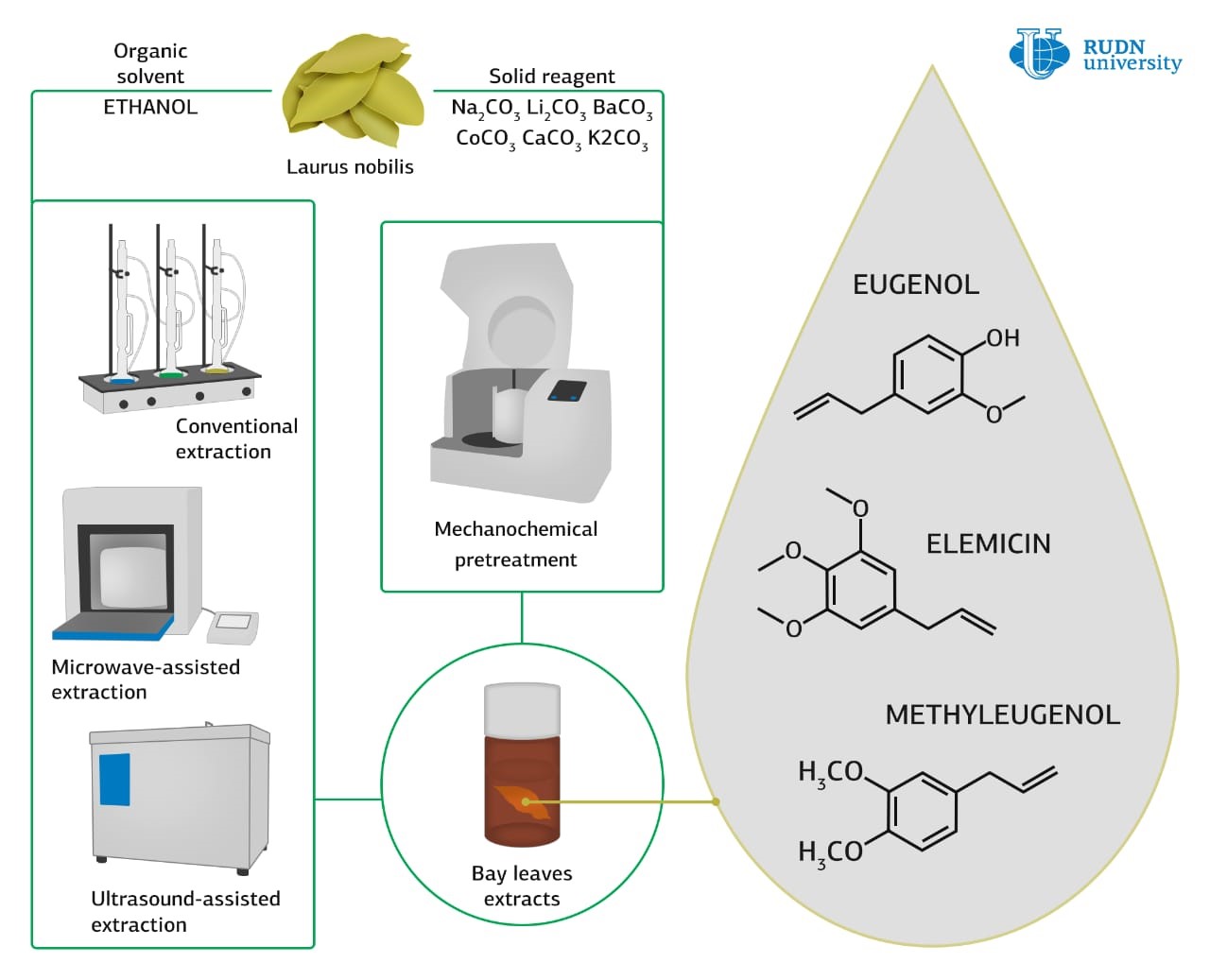

At the first stage of the experiment, the researchers got the extract from leaves using three different solvents: ethanol, methanol and water. Then they used the ultrasonic, microwave, and mechanochemical extraction methods. In the case of the mechanochemical method, the chemists tested different variants of additives — carbonates.

For each of the methods, the authors measured the antioxidant activity of the obtained samples, the total amount of dissolved substances and the amount of phenols. It turned out that the specific antioxidant ability was greater for the extract in ethanol, so in a further study it was ethanol that was used as the main solvent.

Then the chemists investigated the properties of various carbonates as additives for mechanochemical processing. Without carbonates, the extraction is even better than with them, with the exception of lithium carbonate, therefore, Li2CO3 was used as an additive for mechanochemical extraction. The authors then compared mechanochemical processing with microwave and ultrasound processing. In the case of mechanochemical processing, the product yield is higher and the extraction takes less time.

Next, the chemists compared the composition of the extracts obtained by classical, mechanochemical, microwave and ultrasonic extraction. Apparently the main component of the extracts is the by-products formed during the degradation of cell walls. The extracts also contained such essential oils as eucalyptol, eugenol, linalool, and caryophyllene. Eucalyptol and linalool have antimicrobial activity, and eugenol and caryophyllene are among the strongest natural antioxidants. Most target substances and least by-products were extracted by microwave extraction.

The chemists note that mechanochemical extraction is the most promising method for the separation of chemical compounds from plant materials, because with the same content of the necessary substances, the extraction time is reduced by 10 times compared to other technologies. Replacing traditional methods with mechanochemical ones would be a big step forward, since this method meets all the principles of “green chemistry”.

The work was published in the journal Industrial Crops & Products.

Matilda Pavlovna Mityaeva was born in 1925. In November 1942, she volunteered for frontline duty. She participated in the Great Patriotic War from November 1942 to June 1945 as part of the 53rd Infantry Division of the 475th Infantry Regiment. She was wounded twice.

The team led by Sergey Zyryanov, Head of the Department of General and Clinical Pharmacology, became the winner of the All-Russian competition of scientific projects "Technologies for Human Health".

RUDN University constantly adapts to the changes of the modern world and responds to challenges flexibly. This allows us to keep the standard of a world-class research university. The sphere of science is no exception. Peter Dokukin, Head of the Research Division, presented the updated R&D Programme at the meeting of the RUDN University Academic Council.

Matilda Pavlovna Mityaeva was born in 1925. In November 1942, she volunteered for frontline duty. She participated in the Great Patriotic War from November 1942 to June 1945 as part of the 53rd Infantry Division of the 475th Infantry Regiment. She was wounded twice.

The team led by Sergey Zyryanov, Head of the Department of General and Clinical Pharmacology, became the winner of the All-Russian competition of scientific projects "Technologies for Human Health".

RUDN University constantly adapts to the changes of the modern world and responds to challenges flexibly. This allows us to keep the standard of a world-class research university. The sphere of science is no exception. Peter Dokukin, Head of the Research Division, presented the updated R&D Programme at the meeting of the RUDN University Academic Council.