RUDN University chemist created an effective catalyst for the synthesis of organic sulfides

The reduction reaction of organic sulfides from oxides, or deoxygenation of sulfoxides, is a simple direct process of splitting oxygen from organic oxide to produce sulfide. This reaction is important because it occurs in biological processes and in the synthesis of many organic compounds. Organic sulfides are present in most antibiotics, medications, and biological compounds. Sulfides are key intermediates of organic synthesis and important components of many fine chemicals, such as perfumes and cosmetics. Living organisms use an enzyme containing a molybdenum-containing complex to accelerate the reduction of sulfoxides. Molybdenum — based compounds are successfully used in the production of not only synthetic sulfides, but also other classes of important organic compounds-phosphines, olefins. The synthesis of new molybdenum catalysts with improved characteristics based on fundamental knowledge about the mechanisms of deoxygenation is an important and urgent task.

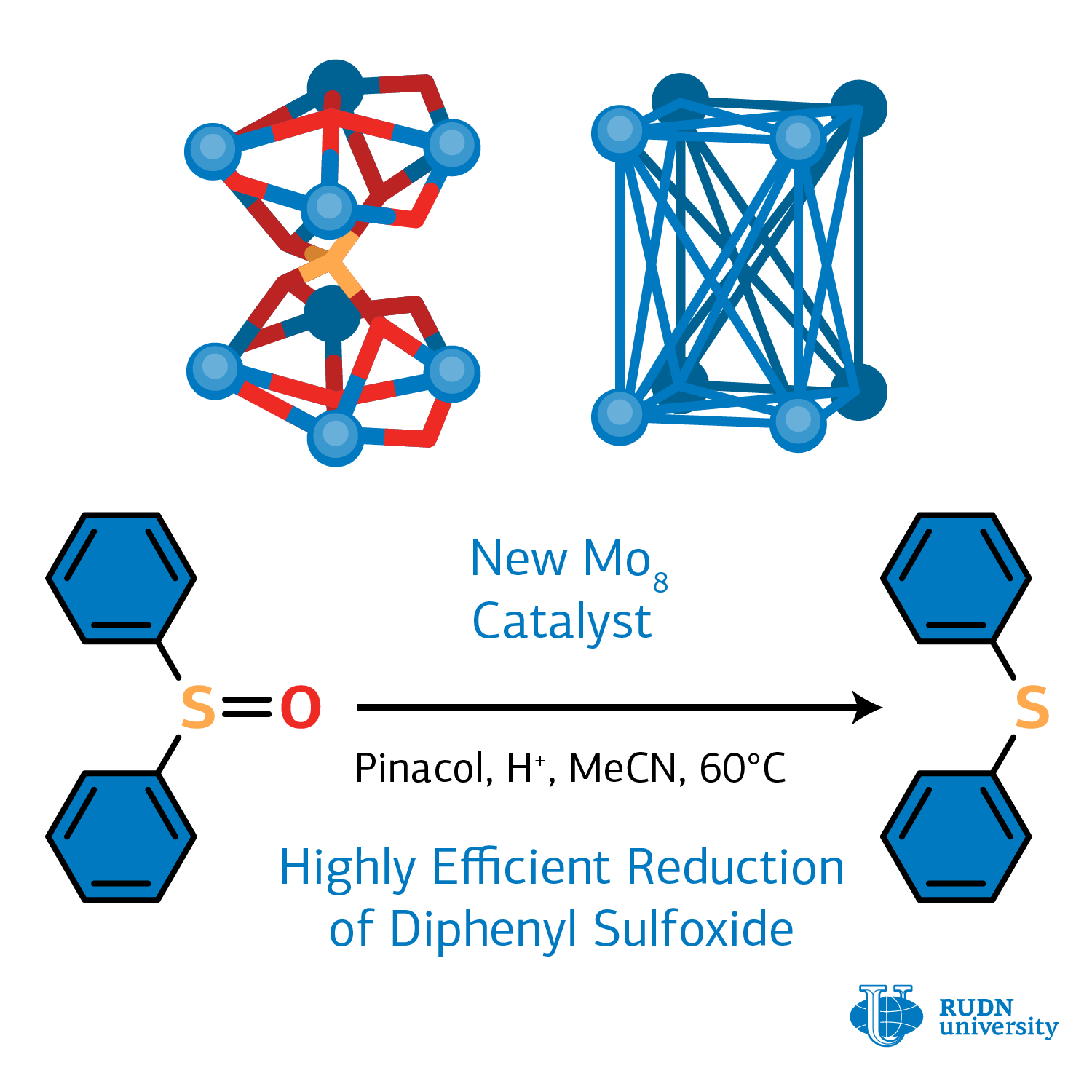

“Modern synthetic chemist, the architect and the Builder. Knowing the properties of building materials — fragments of molecules, it first simulates the structure of a complex molecule, and then collects it. In this work, we were able to obtain a new molybdenum complex in the form of a dumbbell,” the authors of the publication write.

The molybdenum complex was synthesized under hydrothermal conditions (in water and under heating) using salts of molybdenum acid and a number of phosphonic acids that can be converted to phosphate ions. using modern modeling and structural analysis methods, it was possible to classify and accurately determine the structure of a new compound — an eight-core molybdenum cluster, in which four molybdenum cores from below and four from above are connected by a phosphate bridge and additionally stabilized by hydroxyl groups and ammonium ions.

The resulting complex was effective as a homogeneous catalyst in the reduction of diphenyl sulfoxide to diphenyl sulfide. The reaction used a cheap and eco-friendly reducing agent pinacol. By varying various synthesis conditions (duration, temperature, type of solvent, amount of catalyst), chemists were able to achieve a product yield of 99 %. The complex after heat treatment at 310 oC showed another important property — high proton conductivity. Thus, it can be used in obtaining functional membrane materials for creating electrochemical devices — sensors, fuel cells, and supercapacitors.

“After such a remarkable result in the diphenyl sulfide reduction reaction, we tested a catalyst in the reduction of other complex organic sulfides. And we were pleasantly surprised — the yields of the corresponding oxides are also high. The catalyst can be used in the synthesis of even more different substances. In the future, we plan to test this catalyst in other catalytic transformations,” the authors conclude.

Article in the journal of Inorganic Chemistry.

Matilda Pavlovna Mityaeva was born in 1925. In November 1942, she volunteered for frontline duty. She participated in the Great Patriotic War from November 1942 to June 1945 as part of the 53rd Infantry Division of the 475th Infantry Regiment. She was wounded twice.

The team led by Sergey Zyryanov, Head of the Department of General and Clinical Pharmacology, became the winner of the All-Russian competition of scientific projects "Technologies for Human Health".

RUDN University constantly adapts to the changes of the modern world and responds to challenges flexibly. This allows us to keep the standard of a world-class research university. The sphere of science is no exception. Peter Dokukin, Head of the Research Division, presented the updated R&D Programme at the meeting of the RUDN University Academic Council.

Matilda Pavlovna Mityaeva was born in 1925. In November 1942, she volunteered for frontline duty. She participated in the Great Patriotic War from November 1942 to June 1945 as part of the 53rd Infantry Division of the 475th Infantry Regiment. She was wounded twice.

The team led by Sergey Zyryanov, Head of the Department of General and Clinical Pharmacology, became the winner of the All-Russian competition of scientific projects "Technologies for Human Health".

RUDN University constantly adapts to the changes of the modern world and responds to challenges flexibly. This allows us to keep the standard of a world-class research university. The sphere of science is no exception. Peter Dokukin, Head of the Research Division, presented the updated R&D Programme at the meeting of the RUDN University Academic Council.