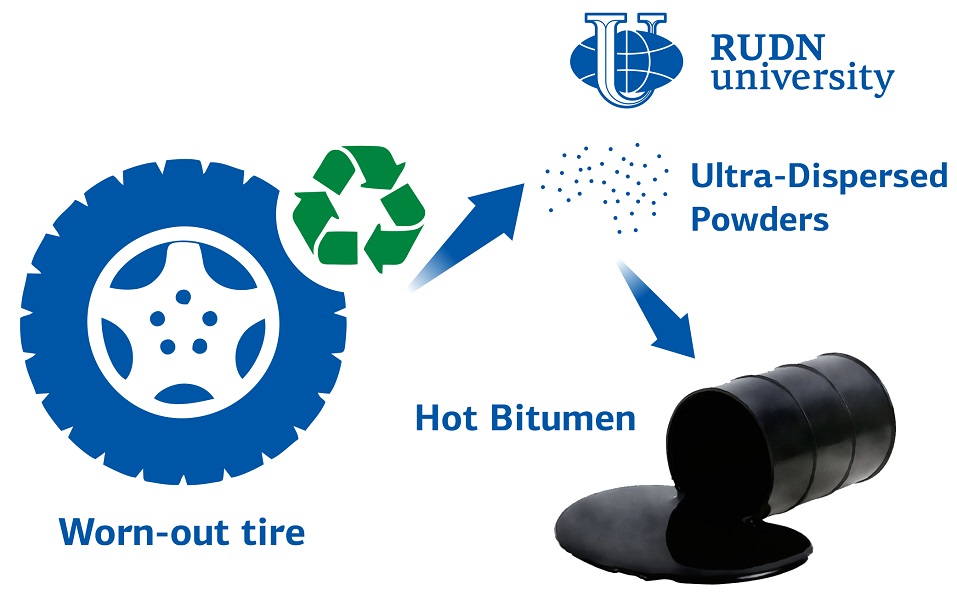

Nanotechnologist at RUDN University has created an asphalt modifier from old tires and rubber

Car tires can be recycled. For example, adding crumb rubber increases the life of asphalt. Typically, tires are crushed to a particle size of a few millimeters. Further grinding is too energy-intensive . However, a new method has emerged — high-temperature shear grinding. It passes with the help of a rotary disperser. The essence of his work lies in strong compression

“Among all the possible applications of crumb rubber from used tires, the most interesting is the use in the road surface. Rubber crumb as a modifier of bitumen and asphalt mixtures increases their service life and has great potential in the road industry. This combines the problems of recycling used tires and improving the durability of roads. In this way, it is possible to reduce the consumption of primary natural resources,” Alexandre Vetcher, PhD, Deputy Director of the Scientific-educational centre “Nanotechnologies”, RUDN University.

Nanotechnologists prepared crumb rubber from car tires, and then crushed it into a powder along with styrene butadiene rubber on a rotary disperser . The powder was added to hot bitumen heated to

RUDN nanotechnologists studied rubber particles before and after their interaction with hot bitumen using scanning electron microscopy. Grinding together with styrene-butadiene rubber leads to the formation of externally homogeneous hybrid particles. After a minute of stirring in hot bitumen, the powder grains are split into pieces

“Considering that one minute of mixing corresponds to the technology for producing various asphalt concrete mixtures, it can be recommended to use additive powders in a ‘dry’ way, that is, to introduce them into the asphalt concrete mixture during its production. It will be more economical. In further studies, we will conduct rheological studies of bitumen with modifiers,” Alexandre Vetcher, PhD, Deputy Director of the Scientific-educational centre “Nanotechnologies”, RUDN University.

The results are published in Polymers.

A RUDN agrotechnologist has identified wheat genotypes that are resistant to a dangerous fungal pathogen that infects plants even before the snow melts and reduces yields.

RUDN University engineers have calculated the parameters of a system that can prevent lunar power plants from overheating. These developments will be needed when planning for long-term lunar missions and colonizing the satellite.

Landfills are the third largest source of anthropogenic methane in the world. They account for ~11% of estimated global emissions. Methane is 80 times more powerful than carbon dioxide and is the second largest driver of man-made climate change. Scientists from around the world met at Zhejiang University's Hangzhou campus to determine the best available technologies for recovering energy and materials from non-recyclable residual waste.